Project Proposal:

My idea for my final project is to design a prototype kinetic sculpture using Solidworks. The form of the sculpture is one that I find my self drawn towards. I want it to look similar to an octopusís tentacles or an umbrella, with a jellyfish like movement created through moving gears located in the middle of the piece.

I drew inspiration for the movement of the piece by watching videos of the kinetic sculptures done by David C. Roy, Bradley N. Litwin and other artists.

http://www.youtube.com/watch?v=Q0OTX4IwSOo = octapult

http://www.youtube.com/watch?v=OMDNppTe2OA

http://www.chrisfitchsculpture.com/pages/Home-TM1.html

1st Update:

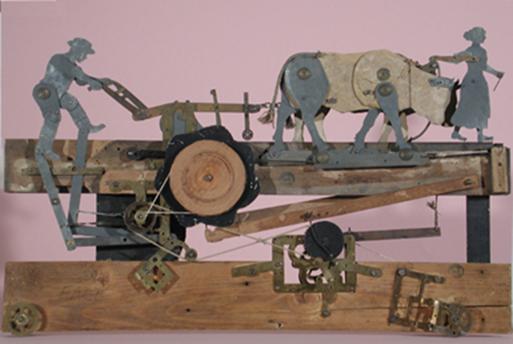

†††††† Iíve started looking at different types of Animatronics and Automata to get ideas for how to design my project.† Some of these automata are amazing for how they are able to create very realistic movement with by very simple mechanical means.

The following Cat and Lion were created using a software called Machineshop:

Shadow puppet type automata:

http://dugnorth.com/blog/labels/antique.html

Clockwork machines are equally fascinating:

http://l3d.cs.colorado.edu/~zathras/research/images.html

http://www.powerhousemuseum.com/hsc/aibo/origins.htm

http://www.automatashop.co.uk/collectors.asp

http://www.brassgoggles.co.uk/brassgoggles/ - gotta love steampunk

http://dugnorth.com/blog/labels/antique.html

http://automata.co.uk/mainpage.html

http://www.forbes.com/fyi/2005/1212/063.html - The Bird Trainer

†

†

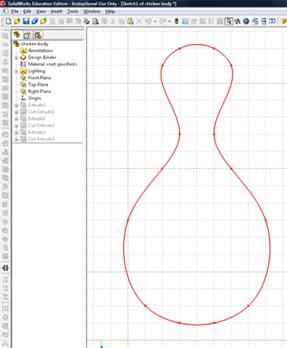

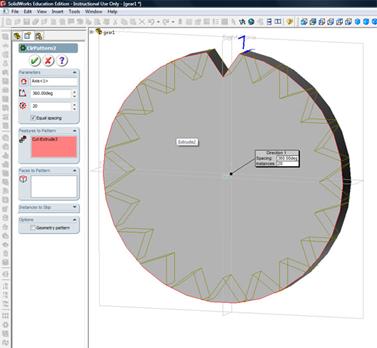

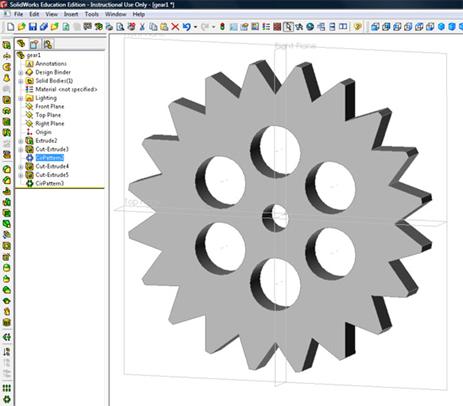

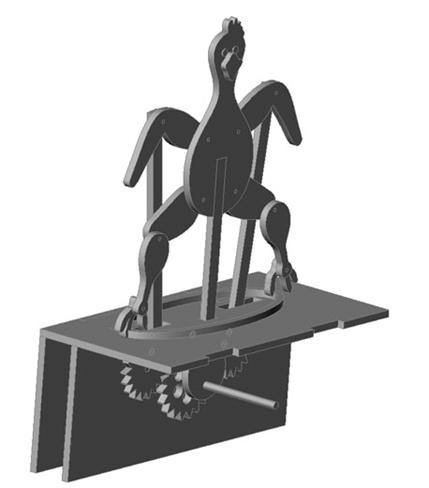

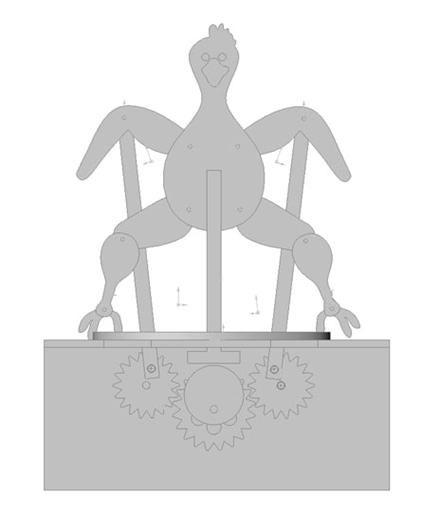

My Idea was to create an automaton of a dancing chicken.† I chose to use Solidworks

for this project because it seemed like it would be the easiest program to design the

gears in and later be able to edit them in order to fit together, which it was.† The ability

to go back and edit any part of the design process at any time became very useful,

especially when certain parts didnít fit together, or when I realized that I made all of

the holes for the connections too large.

†

†

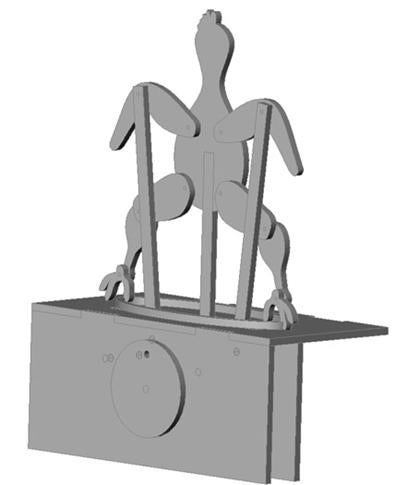

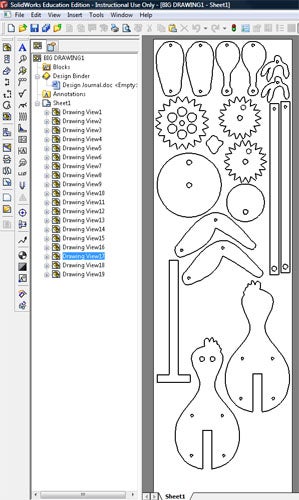

After I had all of the parts designed and put together in the above assembly, all that

was left, was to figure out how to output this design.† My dancing chicken was

designed with output on the laser cutter in mind.† To cut out the pieces on the laser

cutter, I had to create a 2-d vector image that could be used by the laser cutter.

Fortunately, Solidworks also comes with a 2-D drawing feature that allows you

to output vector images for use as blue-prints or other things.† As can be seen

above, I created a document the size of the wood I was going to use, and fit as

many of the parts onto the area as I could.† This document took 6 min each time

the laser cut it, and it took three passes for it to cut all the way through the ľĒ wood.

Curves would cut through the wood faster since the laser would be going minutely

slower along the curves than the straight lines.